Autores

Silva, R.P. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Carvalho, N.P. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Vivan, J.V. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Viroli, S.L.M. (IFTO CAMPUS PARAÍSO DO TOCANTINS)

Resumo

Reverse Logistics reduce pollution by reusing and recycling waste. The quality

and reuse of water discarded during the production of distilled water was

investigated. The study was carried out in an exploratory, descriptive and

quantitative way, evaluating the loss of water during the distillation process in

a Pilsen model water distiller installed in the Food laboratory of the IFTO

campus Paraíso do Tocantins. The pH, turbidity and coliform analyze were

performed according to APHA. The water analysis showed satisfactory potability

quality, and can be reused in washing glassware and producing distilled water. It

is suggested the installation of a reservoir to capture wastewater implanted

below the distiller in the inner part of the laboratory next to the equipment.

Palavras chaves

Water analysis; Distiller; Cooling water

Introdução

Reverse logistics is a set of actions and means aimed at enabling recycling,

reuse, in a sustainable way, requiring a demand for integrated processes to

properly carry out material collection, reprocessing, storage, etc. (MORAIS;

VIDIGAL, 2022). Reverse logistics integrates recycling and correct disposal of

products in their final stage, this means that it is the moment in which the

residue from the consumed product returns to the company, so that it can be

reused, generating raw material or correctly discarded so as not to cause an

impact. environment (RODRIGUES, 2022). In a practical way, Reverse Logistics

aims to reduce pollution, promote the reuse and recycling of waste while

improving the organization's brand and image (NASCIMENTO et al, 2019). Damaged

glassware, solid chemical reagents, liquids and materials used for didactic

purposes in practical chemistry classes generate large amounts of organic and

inorganic materials within educational institutions that need proper treatment

and disposal (LINHARES et al, 2008). The management of waste generated by

Universities, Federal Institutes and Research Centers cannot be neglected, as

waste from chemical products and broken glassware produced in their chemical

laboratories can cause enormous environmental impacts if improperly disposed of

in the environment. (LINHARES et al, 2008). Most of the waste generated during

classes can be recycled or reused (LEITE, 2003). In view of this context, the

practices to reduce waste and rational use of resources were analyzed, the

quality and possibility of reuse of discarded water during the distilled water

production process were researched.

Material e métodos

The study was carried out in an exploratory and descriptive manner with a

quantitative approach (GIL, 2008) evaluating the loss of water during the

distillation process in a Pilsen model water still, with a maximum distillation

capacity of 5 liters per hour (L.h)-1), producing 10 liters of

distilled water running 4 (four) hours a day, installed in the Food Laboratory of

the Federal Institute of Education, Science and Technology (IFTO) on the Paraíso

do Tocantins campus. The amounts of distilled and cooling water were based on the

calculation of the flow during the distillation process. Flow tests were carried

out, where the water was collected in a graduated container, timing the time of

15, 30, 45 and 60 minutes uninterruptedly. For each time, the volume of distilled

and cooling water from the still was measured. After the flow measurements, the

costs with the cooling water discarded by the distiller were compared with the

cost of the treated drinking water. The distiller's efficiency was also verified,

being calculated through the flow in L.h-1 of the distilled water, in

which the food laboratory distiller, according to the manufacturer's manual,

distills 5 L.h-1 when it is working with 100% efficiency. From this

information, it was possible to calculate the operating efficiency of the

distiller. Potential hydrogenonic (pH), turbidity and total (TC) and

thermotolerant (CTT) coliform (CTT) analyzes were performed following the

methodologies of the American Public Health Association (APHA, 2012). The results

of the analyzes were compared with the values of the Consolidation Ordinance No.

05, of September 28, 2017 (BRASIL, 2017). Finally, actions were proposed to

mitigate the waste and reuse of water discarded by the distiller.

Resultado e discussão

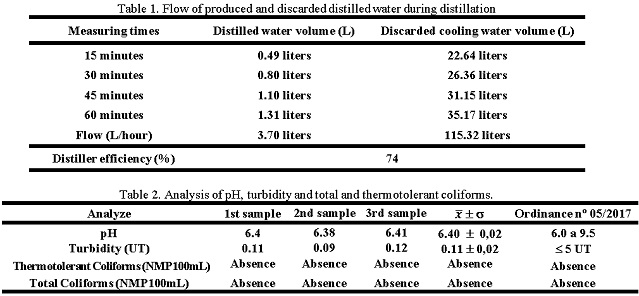

Tables 1 and 2 show the results of the still flow test and analysis of pH,

turbidity and total and thermotolerant coliforms, respectively. For the storage

of water for reuse, 50 L barrels were used (figure 1). The distiller showed an

efficiency of 74% producing 3.70 L of distilled water and 115.32 L of water per

hour. 31.16 liters of well water were needed to produce 1 liter of distilled

water. In one month, running 4 hours a day, we will have a disposal of 13.84

m3 of cooling water, which is equivalent to BRL 86.10 reais (BRK,

2021). The results of the analysis of pH, turbidity and total and thermotolerant

coliforms show compliance with the aforementioned legislation, which establishes

the potability parameters. Simões et al (2020), conducting a study on the

analysis of the quality of water discarded in the process for the production of

distilled water, found an efficiency of 73% with production of 3.65 L of

distilled water and disposal of 105.97 L of water, requiring 29 , 02 L of well

water to produce 1 liter of distilled water. According to Pinto, Capri and Capri

Neto (2015) the water discarded from the distillers is not contaminated and has

the characteristics of drinking water. Rodon, Ribeiro Junior and Silva (2017),

Medeiros, Storck, Volpatto, (2017) researching on the reuse of wastewater from

distillers report, it can be reused for cleaning instruments, benches and

equipment used in tests, washing glassware in laboratories and for further

distillations. They corroborate the statements of the authors cited with the

results obtained in this study, using cooling water discarded from the

distillers. Reuse must be practiced in laboratories, and must be designed in the

implementation and construction phase of institutions (SIMÕES et al, 2020).

Table 1. Flow of produced and discarded distilled water during distillation. Table 2. Analysis of pH, turbidity and total and thermotolerant coliforms

Storage of discarded water in the still during the distilled water production process

Conclusões

Given the need for distilled water in the laboratories of the IFTO campus Paraíso

do Tocantins and under the efficiency of the distiller installed in the food

laboratory, there is a waste of 13,000 liters of water, generating a monthly

expense of 86.10 reais. The water analysis showed that the water from the

distiller's refrigeration disposal has satisfactory quality compared to

potability standards, and can be reused for the purpose of washing laboratory

glassware and recirculation in the distiller itself to produce distilled water.

It is suggested, for future works, the installation of a res

Agradecimentos

TO GOD, to the IFTO Paraíso do Tocantins campus

Referências

APHA. American Public Health Association. Standard Methods for the Examination of Water and Wastewater. 22 ed. Washington DC, 2012.

BRK. Tabelas de tarifas – BRK/Saneatins Tocantins. Disponivel em: https://brkambiental.com.br/uploads/31/ santa/

estrutura-tarifaria-tocantins-12-2021.pdf. Acesso em: 5 maio 2022

BRASIL. Ministério da saúde. Portaria de Consolidação nº 05, de 28 de setembro de 2017. Consolidação das normas sobre as ações e os serviços de saúde do Sistema Único de Saúde. Brasília: Diário Oficial da União, 03 out. 2017.

GIL, A. C. Métodos e técnicas de pesquisa social. Antônio Carlos Gil. - 6. ed. - São Paulo: Atlas,2008.

LEITE, P. R. Logística Reversa: Meio Ambiente e competitividade. São Paulo: Prentice Hall, 2003.

LINHARES, A. C. S.; CARDOSO, P. A.; JUNIOR, O. C . Logística reversa: o caso do destino de produtos químicos e vidrarias de uma instituição de ensino profissionalizante em Curitiba. In: ENCONTRO NACIONAL DE ENGENHARIA DE PRODUÇÃO, 28, 2008, Rio de Janeiro. Anais Eletrônicos [...]. Rio de Janeiro, 2008. Disponível: https://abepro.org.br/biblioteca/enegep2008_tn_sto_077_540_11254.pdf. Acesso 12 mar. 2022

MEDEIROS, R. C.; STORCK, W. R.; VOLPATTO, F. Gestão da água de descarte de destiladores de água em Laboratórios de uma IES. In: CONGRESSO BRASILEIRO DE GESTÃO AMBIENTAL, 8., 2017 Campo Grande. Anais...Mato Grosso do Sul: IBEAS, 2017. p.1-4. Disponivel em : https://www.ibeas.org.br/congresso/Trabalhos2017/I-015.pdf. Acesso em: 2 maio 2022.

MORAIS, M. de O.; VIDIGAL, H. . Logística Reversa e Resíduos Sólidos: a importância da conscientização sobre a reciclagem do vidro. Pesquisa, Sociedade e Desenvolvimento. [S. l.] , v. 11, n. 5, pág. e57611528829, 2022. DOI: 10.33448/rsd-v11i5.28829. Disponível em: https://rsdjournal.org/index.php/rsd/article/view/28829. Acesso em: 8 jun. 2022.

NASCIMENTO, M. C.; DOS SANTOS, M. A.; FERREIRA, G. S. A. A Logística Reversa e os Fatores Socioambientais e Econômicos: um estudo de empresas do setor cosméticos e de óleo vegetal. In: Simpósio de Tecnologia da Fatec Sertãozinho, 2(1), 343-353. 2019. https://doi.org/10.33635/sitefa.v2i1.82. Acesso 22 maio 2022.

PINTO, A. C.; CAPRI, M. R.; CAPRI NETO, A. Gestão de água no laboratório: recuperação da água descartada dos destiladores. In: CONGRESSO INTERNACIONAL RESAG – Gestão da água e monitoramento ambiental, 2., 2015, Aracajú. Anais... Aracajú –SE: UNIT, 2015. Disponível em: http://www.resag.org.br/congressoresag2015/anais/img/pdfs

/ID_136.pdf. Acesso em: 2 maio 2022.

RONDON, H. A.; RIBEIRO JUNIOR, I.; SILVA, M.; R.;da. Implantação de um sistema de reúso da água residual do aparelho destilador para laboratório de solos do IFMT. In: ENCONTRO EM ENGENHARIA DE EDIFICAÇÕES E AMBIENTAL – EEEA, 5., 2017, Cuiabá. Anais... Cuiabá–MT: UFMT, 2017. Disponível em: http://eventosacademicos.

ufmt.br/index.php/eeea/eeea 2017/paper/view/5730 Acesso em: 10 abr. 2022

RODRIGUES, RO. Logística Reversa como diferencial competitivo. Pesquisa, Sociedade e Desenvolvimento, [S. l.] , v. 11, n. 6, pág. e36311629354, 2022. DOI: 10.33448/rsd-v11i6.29354. Disponível em: https://rsdjournal.org/index.php/rsd/article/view/29354. Acesso em: 8 jun. 2022.

SIMÕES, F. A. F.; DE FREITAS, C. A. S.; FEITOSA, R. G. F.; SANTOS, Y. T. da C.; COSTA, L. D. A.; PINHO, C. de O.; da SILVA, M. L. Q.; dos SANTOS, S. P. Potencial de reúso das águas de resfriamento de destiladores laboratoriais. Revista Eletrônica de Gestão e Tecnologias Ambientais, [S. l.], v. 8, n. 1, p. 180–194, 2020. DOI: 10.9771/gesta.v8i1.36627. Disponível em: https://periodicos.ufba.br/index.php/gesta/article/view/36627. Acesso em: 05 maio. 2022.