Autores

Conceição, V.S. (INSTITUTE OF CHEMISTRY, UNIVERSITY OF SÃO PAULO) ; Bertotti, M. (INSTITUTE OF CHEMISTRY, UNIVERSITY OF SÃO PAULO)

Resumo

Quantitative analytical methods free of reagents, washing, or calibration steps

contributing to the minimization of waste generation are very attractive.

Accordingly, this work proposes a proof-of-concept study toward quantitative

determinations with a microelectrode through only one single chronoamperogram. A

thickener was added to potassium ferricyanide solutions to change the viscosity

and mimic a complex sample medium. The concentration values calculated using the

proposed calibration-free method were in satisfactory agreement with the

theoretical value (maximum deviation of 9.8%). Hence this seems to be a simple and

promising method to obtain reliable and quantitative information without

calibration protocols.

Palavras chaves

calibration-free; microelectrodes; electrochemical

Introdução

Analytical methods are fundamental for getting quantitative information regarding

chemical species in environmental compartments and foods (SKOOG et al., 2006).

Quantitative analyzes usually require calibration curves, resulting in excessive

use of reagents, waste generation, and long time. In more complex matrices, using

calibration plots may lead to more significant analytical errors. A possibility to

circumvent such a problem relies on direct methods, such as coulometry and

gravimetry. However, these methods are sensitive to the presence of contaminants

and require long analysis times to ensure that the target analyte undergoes the

reaction of interest. The interferent removal to isolate the analyte can be

accomplished by using separation, extraction, and purification methods, which are

slow and require the use of organic solvents that are harmful to the environment

and to life (MOTSHAKERI et al., 2019). Taking these aspects into account, we show

in this work our efforts in the attempt to develop an easy quantitative

electrochemical method that does not depend on extended analysis time and is

calibration-free.

Material e métodos

Microelectrode manufacturing: The microelectrodes were homemade by

attaching a commercial carbon microfiber (r = 5 μm) to a nickel-chromium wire

using silver glue. The microfiber was inserted into a 100 μL micropipette

plastic tip. To ensure electrical contact between the nickel-chromium wire and

the microfiber and to avoid any damage, carbon black was also added inside the

micropipette. The micropipette was then completely filled with Araldite epoxy

glue, and the system was sealed with parafilm. Preparation of solutions:

Potassium ferricyanide (K3[Fe(CN)6]) solutions of well-

known concentrations were carefully prepared in 1.0 M KCl medium. Ethylene

glycol thickener was added to the solutions (10% (v/v)) to simulate a different

chemical environment, as the response in electrochemical measurements (current)

depends on the viscosity. The solutions were prepared from analytical grade

reagents dissolved in deionized water (processed in a Nanopure Infinity system,

Barnstead). Potassium chloride and potassium ferricyanide were purchased from

Sigma-Aldrich® and ethylene glycol from Vetec®. Electrochemical Measurements:

All experiments were performed using an AUTOLAB PGSTAT128N potentiostat

(Metrohm Brazil). The electrochemical experiments were carried out in a typical

cell with three electrodes: work, reference, and platinum wire counter

electrode. All potentials are reported against a Ag/AgCl (saturated KCl)

reference electrode prepared by electrodeposition of AgCl on a silver wire,

which was then placed in a micropipette tip containing a KCl saturated solution.

Resultado e discussão

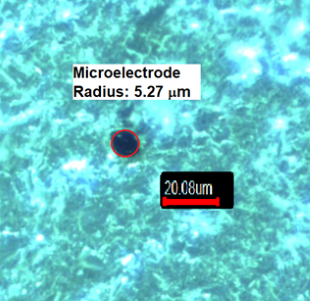

Microelectrode radius: Figure 1 shows the optical microscopy image of a

carbon fiber disk microelectrode. The microelectrode radius value was found to

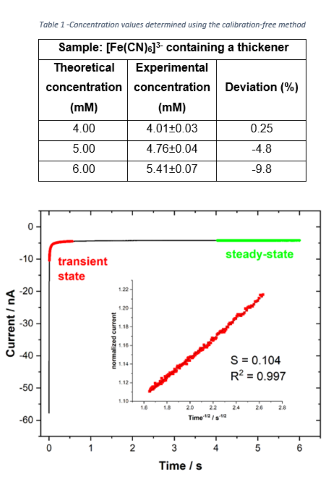

be 5.27 μm. Development of the calibration-free method: The proposed

calibration-free method relies on the measurement of the steady-state current

(IL) at a disc microelectrode, as follows: IL = 4nFDCr

(Equation 1) where F is the Faraday constant, D is the diffusion coefficient, n

is the number of electrons involved in the electron-transfer step, C is the bulk

concentration of the electroactive species, and r is the radius of the

microelectrode. The radius value can be precisely determined by optical

microscopy or electrochemical methods – instead of using the value provided by

the manufacturer - and the n value can be obtained through knowledge of the

electrochemical reaction. Information on the diffusion coefficient is difficult

to obtain since D depends on the sample medium. However, such value can be

extracted from the chronoamperogram based on a methodology proposed by Denuault

and coauthors (1991). The linearization of the transient region in the

chronoamperogram (current (i/t) normalized by the steady-state

current (IL) as a function of t-½) (Figure 2) allows

calculating the diffusion coefficient (D) according to the expression: D =

πr2/16S2 (Equation 2) where S is the slope of the straight

line (inset of Figure 2). Taking into account the calculated diffusion

coefficient and by using Equation 1, the concentration of the target analyte can

be easily determined. In short, all parameters necessary to calculate the

analyte concentration are taken from only one chronoamperometric experiment,

without the need for a calibration curve since IL and D are obtained

by chronoamperometry, r is a geometric value, F is a constant, and the number of

electrons (n) is defined based on the redox process involving the species of

interest. Concentration: From the information obtained by

chronoamperometry, the concentration of the electroactive species was

determined, as shown in Table 1 (n = 5 independent experiments). The

concentration values found are within an acceptable error, less than 10%. The

calibration-free methodology allows calculating the diffusion coefficient using

Equation 2. For the experimental conditions of this experiment (1 M KCl; 10%

ethylene glycol), the diffusion coefficient found for ferricyanide was (5.3±0.2)

x 10-6 cm2 s-1. Such a value is lower than the

one in pure aqueous solution (6.32 x 10-6 cm2

s-1 in 1 M KCl) (ADAMS, 1969), which is expected considering the

increase in the viscosity.

Figure 1 - Optical microscopy image of a carbon microelectrode (400x)

Figure 2 -Chronoamperometry in 4.0 mM ferricyanide (in 1.0 M KCl) with 10% (v/v) of thickener. E = -0.1 V.Inset: Linearization of the transient region

Conclusões

The proof-of-concept experiments yielded satisfactory results in good agreement

with the expected values. Therefore, the presented method has great potential to

be applied in the quantitative determination of electroactive chemical species. In

addition to optimizing the process, since the chronoamperometry analysis is

performed in less than 1 min, the proposed methodology contributes to Green

Chemistry by minimizing the reagents and waste disposal from solutions used to

perform calibration plots.

Agradecimentos

The authors would like to thank the São Paulo State Research Foundation (FAPESP

2018/08782-1), the National Council for Scientific and Technological Development

(CNPq) and CAPES (CODE - 0561/2021) for the generous funding.

Referências

ADAMS, R.N. Electrochemistry at Solid Electrodes. Marcel Dekker. New York, 1969.

SKOOG, D.A.; WEST, D.M.; HOLLER, J.; CROUCH, S.R. Fundamentos de Química Analítica. Tradução da 8ª edição norte-americana. Editora Thomson, p. 2, 2006.

Denuault, G; Mirkin, M.V., Bard, A.J. Direct Determination of Diffusion Coefficients by Chronoamperometry at Microdisk Electrodes. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry, 308, p. 1-2, 1991.

MOTSHAKERI, M.; PHILLIPS, A. R.J.; KILMARTIN, P. A. Application of Cyclic Voltammetry to Analyse Uric Acid and Reducing Agents in Commercial Milks. Food Chemistry, v. 293, p. 23-31, 2019.