Autores

Pereira, F.S. (UNIVERSIDADE FEDERAL DO MARANHÃO) ; Lima, S.L.S. (PONTIFÍCIA UNIVERSIDADE CATÓLICA DO RIO DE JANEIR) ; Tanaka, A.A. (UNIVERSIDADE FEDERAL DO MARANHÃO) ; Garcia, M.A.S. (UNIVERSIDADE FEDERAL DO MARANHÃO) ; Silva, A.G.M. (PONTIFÍCIA UNIVERSIDADE CATÓLICA DO RIO DE JANEIR)

Resumo

The present investigation shows that high catalytic activity can be reached

towards the ORR by employing 1.8 ± 0.7 nm Ir nanoparticles (NPs) deposited onto

MnO2 nanowires surface under low metal loadings (1.2 wt.%). Interestingly, we

observed that the MnO2-Ir nanohybrid presented high catalytic activity for the ORR

close to commercial Pt/C (20.0 wt.% of Pt), indicating that it could obtain

efficient performance using a simple synthetic procedure.

Palavras chaves

Manganese dioxide; iridium; ORR

Introdução

In general, ORR mainly occurs through two pathways, one involving the transfer

of two electrons (2e− ORR), producing H2O2, and the other consisting of the

transfer of four electrons (4e− ORR), yielding H2O as the product [1].

Therefore, developing electrocatalysts to undergo this pathway is critical for

the optimal electrochemical performance of fuel cells. However, the ORR limits

the performance of many electrochemical devices due to its sluggish kinetics,

which results in considerable overpotentials, causing a significant loss in

energy efficiency; thus, the design of transition metal-based nanomaterials is

pervasive [2, 3]. Manganese dioxide (MnO2) is a promising candidate as an

electrocatalyst for ORR because, in addition to the low cost associated with the

abundance in the form of natural ores, it has environmental compatibility, low

toxicity, and variable oxidation states [4]. However, its major limitation is

the low electronic conductivity, which is unfavorable for rapid electron

transfer during the electrochemical process [5]. A strategy to solve the MnO2

low electronic conductivity is to deposit small amounts (<2.0 wt.%) of some

transition metals. Among them, iridium (Ir) is a promising candidate due to its

higher availability than Pt, lower costs, and suitable activities for the ORR

[6].

Material e métodos

Synthesis of MnO2 Nanowires

In a typical procedure, MnSO4·H2O and KMnO4 were dissolved in deionized water.

This solution was transferred to a Teflon-lined stainless steel autoclave that

was heated and stirred and then allowed to cool down to room temperature. The

nanowires were washed with ethanol and water several times by centrifugation and

removal of the supernatant and finally dried in air.

Synthesis of MnO2 Nanowires Decorated with Ir NPs (MnO2–Ir NPs)

MnO2 nanowires and polyvinylpyrrolidone (PVP) were added to EG. The obtained

suspension was transferred to a round-bottom flask and kept under vigorous

stirring. Then, NaBH4 and IrCl3− solutions were sequentially added to the

reaction flask. This mixture was kept under vigorous stirring to produce MnO2–

IrNPs and washed with ethanol and water by rounds of centrifugation and removal

of the supernatant. After washing, the MnO2–Ir NPs were suspended in water.

Electrochemical Studies

Electrochemical experiments for ORR were performed in a conventional three-

electrode cell using a PGSTAT 302 N (Autolab) potentiostat/galvanostat model

controlled by Nova 2.0 soft-ware and the electrode rotation rate by a Pine ASR

rotator. A potassium hydroxide (KOH) solution was used as the electrolyte,

modified glassy carbon as the working electrode, a platinum wire as the counter

electrode, and saturated AgCl/KCl as the reference electrode. A total of 20 μL

of paint (mixed solution containing 5 mg of the material of interest, 1 mg of

methanol with 0.1 mL of Nafion® 5.0% by weight, and 1.4 mL of deionized water,

dispersed by ultrasound for 10 min) was used to modify the surface of the glassy

carbon electrode.

Resultado e discussão

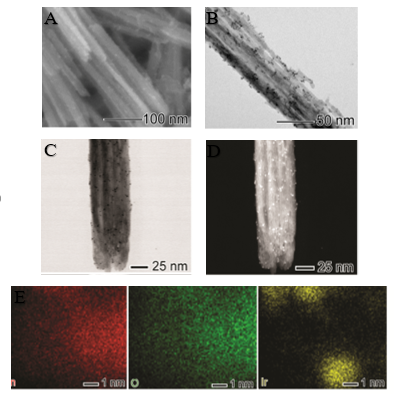

Figure 1 shows SEM and TEM images of the ultrasmall Ir NPs deposited on MnO2

nanowires. A uniform distribution of monodisperse ultrasmall NPs with a narrow

size distribution all over the surface of the nanowire with particles size of

1.8 ± 0.7 nm. High-angle annular dark field images and scanning transmission

electron microscopy analyses were performed to investigate further the structure

and Mn, O, and Ir elemental distributions in the MnO2 decorated with Ir NPs.

Bright-field STEM (Figure 1C) and HAADF-STEM (Figure 1D) images illustrate the

uniform distribution of ultrasmall Ir NPs at the MnO2 nanowires support. No

significant agglomeration was detected. In addition, STEM-EDS elemental mapping

(Figure 1E) confirmed the uniform deposition of ultrasmall Ir NPs of ultrasmall

Ir NPs over the outer surface of the MnO2 nanowires. No morphological changes in

the nanowire shape could be detected after Ir NPs deposition.

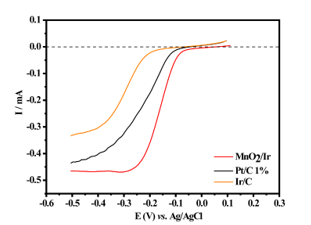

When MnO2 nanowires and MnO2-Ir electrocatalyst were compared with the

commercial Pt/C electrocatalyst, one can notice that the MnO2-Ir nanowires

presented a lower onset potential and higher limiting current, showing its

incredible efficiency (Figure 2). We also compared the MnO2-Ir nanowires with

the 20.0 wt.% Pt/C which presented current and potential density close to the Pt

counterpart. The results were presented in current, without considering the mass

of precious metal. However, such a commercial electrocatalyst offers 20 times

more metal loading than the MnO2-Ir electrocatalyst produced in the present

work, showing the effectiveness of our material. The polarization curve of

material is analogous to the Pt/C counterpart, suggesting that the

electrocatalyst can catalyze a 4e− ORR process for reagent molecule.

SEM images of MnO2-Ir nanowires (A) and TEM (B). BF- STEM (C) and HAADF-STEM (D) and STEM-EDS (E) maps of Mn (red), O (green), and Ir (yellow).

Polarization curves for the ORR on MnO2, MnO2-Ir,and 1.2 wt.% Pt/C materials, in 0.1 mol L−1 KOH solution, f = 1600 rpm in room temperature.

Conclusões

In conclusion, the present investigation demonstrated that MnO2 nanowires

decorated with Ir NPs could be employed as heterogeneous electrocatalysts for the

oxygen reduction reaction, being a promising nanocatalyst compared to commercial

platinum. Through a simple synthesis, it was possible to obtain nanowires with

defined shape and size that could serve as templates for Ir NPs nucleation and

growth without any surface modification, which oxidize to IrO2 while MnO2 is

reduced.

Agradecimentos

Referências

[1] Li, Y.; Li, Q.; Wang, H.; Zhang, L.; Wilkinson, D.P.; Zhang, J. Recent Progresses in Oxygen Reduction Reaction Electrocatalysts for Electrochemical Energy Applications. Electrochem. Energy Rev. 2019, 2, 518–538.

[2] Stacy, J.; Regmi, Y.N.; Leonard, B.; Fan, M. The Recent Progress and Future of Oxygen Reduction Reaction Catalysis: A Review. Renew. Sustain. Energy Rev. 2017, 69, 401–414.

[3] Xia, Y.; Yang, X. Toward Cost-Effective and Sustainable Use of Precious Metals in Heterogeneous Catalysts. Acc. Chem. Res. 2017,50, 450–454.

[4] Goswami, C.; Hazarika, K.K.; Bharali, P. Transition Metal Oxide Nanocatalysts for Oxygen Reduction Reaction. Mater. Sci. Energy Technol. 2018, 1, 117–128

[5] Cheng, F.; Su, Y.; Liang, J.; Tao, Z.; Chen, J. MnO2-Based Nanostructures as Catalysts for Electrochemical Oxygen Reduction in Alkaline Media. Chem. Mater. 2010, 22, 898–905.

[6] Wang, Z.; Gao, W.; Xu, Q.; Ren, X.; Xu, S.; Zhu, S.; Niu, X.; Li, X.; Zhao, R.; Han, Y.; et al. Influence of the MnO2 Phase on Oxygen Evolution Reaction Performance for Low-Loading Iridium Electrocatalysts. ChemElectroChem 2021, 8, 418–424.