Autores

Gamboa Suárez, M.A. (UNIVERSIDAD INDUSTRIAL DE SANTANDER) ; Combariza, M.Y. (UNIVERSIDAD INDUSTRIAL DE SANTANDER) ; Blanco Tirado, C. (UNIVERSIDAD INDUSTRIAL DE SANTANDER)

Resumo

Bacterial cellulose (BC) is a biodegradable polymer that can be synthesized from

agro-industrial waste. However, its hydrophilic nature limits its application in

areas such as food packaging, where moisture control is essential. In this

contribution, we test the effect of BC surface modification on the production of

a hydrophobic material. The formation of amides, from amines coupled to

carboxylic units of oxidized cellulose BC-TEMPO (BC-TOCN), allows modulating its

hydrophilic properties.

Characterization by IR, TGA, SEM and DLS suggests an effective modification of

its surface. Contact angle (CA) and surface free energy (SFE) analysis indicate

changes in hydrophobicity. Amidation increases the contact angle from 29° for

BC-TOCN to 80° with BC-TOCN-AMD C-12 and 147° with BC-TOCN-AMD C-18.

Palavras chaves

Bacterial cellulose ; amidated cellulose ; hydrophobization

Introdução

Plastic waste's pollution of surface waters is rising at the planetary level.

Synthetic plastics are recalcitrant to microbial degradation and generate CO2

emissions causing negative impacts on ecosystems (COSTELLO, et al., 2009; SHEN,

et al., 2020). Biodegradable polymers (PBs) emerge as a solution to pollution by

synthetic plastic waste. The production of PBs by biotechnological pathways

using inexpensive carbon sources, especially by-products of agro-industrial

processes, is a very active research area. Colombia is a country with an

agricultural vocation with abundant residual biomass. Cacao beans production

generates by-products such as cocoa mucilage exudate (CME), a liquid with high

nutrient content, valuable as a carbon source for culture media in

biotechnological processes. We previously demonstrated the use of CME for

bacterial cellulose (BC) production.

Structurally similar to plant cellulose, BC is a linear homopolymer formed by

condensation of glucose molecules. BC is produced, by static or dynamic

fermentations, by a group of microorganisms, among which the Gluconacetobacter

xilynus stands out (SAAVEDRA SANABRIA, et al., 2021).

BC exhibits good mechanical properties, high crystallinity, non-toxicity,

biocompatibility, and biodegradability. BC finds uses in many areas, such as

cosmetics, pharmaceuticals, biomaterials, and medicine (WANG, TAVAKOLI, & TANG,

2019). However, BC's hydrophilic nature restricts its use in specific

applications such as food packaging, particularly for products susceptible to

moisture damage. Thus, BC hydrophobization can modulate its hydrophobic

character and improve its properties as an additive in biodegradable flim

packaging materials (BALASUBRAMANIAM, PATEL, & NAYAK, 2020).

Currently, several techniques are documented to improve BC´s moisture barrier

capacity, such as esterification with organic acids (PENG, CHANG, KUMAR, MOON, &

YOUNGBLOOD, 2016), amination (SIRVIO, VISANKO, LAITINEN, AMMALA, & LIIMATAINEN,

2016) and surface amidation (TAUBNER, COPÍKOVÁ, HAVELKA , & SYNYTSYA, 2013). We

previously reported a surface amidation strategy to modify commercial

microcrystalline cellulose, and Fique fibers cellulose using TBTU uronium salt

[O-(1H benzotriazol-1-yl)-N, N,N',N'-tetramethyluronium tetrafluoroborate] as

coupling agent, TEMPO-oxidized nanocellulose (BC-TOCN), and a primary amine

(GÓMEZ, COMBARIZA, & BLANCO TIRADO, 2017). The modified material exhibits

increased contact angle values, up to five times higher than the CA for the

unmodified BC. This material displays favorable properties such as

biodegradability and hydrophobicity, making it a potential additive for food

packaging. On the other hand, BC is produced using CME, a residual by-product

from the cocoa bean processing, thus avoiding the negative environmental impacts

associated with discarding effluents with a high organic load into soils and

surface water.

Material e métodos

• Bacterial cellulose

The BC was biosynthesized by Gluconacetobacter xylinus in reactors with an

operating volume of 3 L containing a supplemented medium and CME as a carbon

source. BC is produced extracellularly; the film is washed and sterilized once

the process finishes.

• Bacterial cellulose TEMPO oxidation

TEMPO ( 0.016 g) and NaBr (0.1 g) were added to a 1% (w/v) BC aqueous

suspension. NaClO was added to the mixture dropwise, maintaining a molar ratio

of 1:6 cellulose: NaClO. The reaction flask was placed in an ultrasonic bath for

four hours while keeping the pH at 10.5 by NaOH addition. pH stabilization

indicates reaction completion; at this point, ethanol is added to stop the

catalytic reaction cycle. The reaction mixture was centrifuged, and the solid

was washed with water and HCl (0.1 M) until neutral pH. Finally, an ultrasonic

probe was used to obtain a uniform dispersion of BC-TOCN.

• BC-TOCN amidation

TBTU dissolved in dimethylformamide (DMF) was added to a BC-TOCN solution in a

2:1 TBTU:BC-TOCN molar ratio. The reaction mixture was stirred at room

temperature for 30 minutes, keeping the pH basic. A primary amine solution

(dodecylamine or octadecylamine) in DMF (molar ratio 4:1 amine group:COOH units

in BC-TOCN), was added under constant stirring at room temperature for 2 hours.

The solution was then filtered and washed with methanol, HCl, and water to

eliminate unreacted amines. Finally, frozen and lyophilized materials were

labeled BC-TOCN AMD C-12 and BC-TOCN AMD C-18.

• Characterization

The degree of oxidation and the colloidal stability of the BC-TOCN were

evaluated by means of conductometric titration curves and ζ potential

measurements, respectively. Thermal stability was also tested by

thermogravimetry (TGA). The morphological changes and dimensions of the modified

cellulose surface were observed by scanning electron microscopy (SEM). Likewise,

its structure was studied by means of infrared spectroscopy (FT-IR) and X-ray

diffraction (XRD). Additionally, the hydrophobicity of the materials was

evaluated with contact angle measurements.

Resultado e discussão

Bacterial cellulose TEMPO oxidized nanofibers (BC-TONC) exhibit a degree of

oxidation (OD) of 0.26 and 1.53 mmol of COOH/g of cellulose. These

characteristics indicate a reactive surface loaded with carboxylic groups,

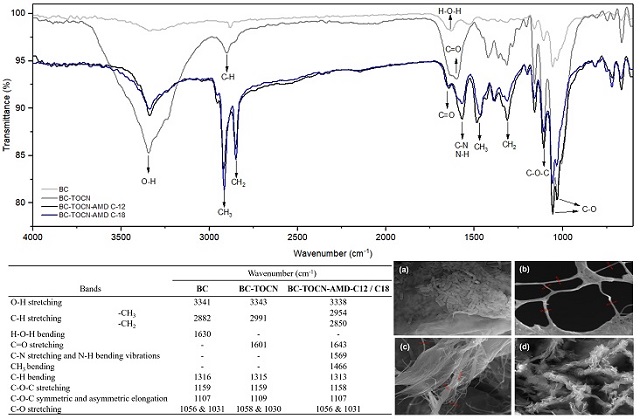

suitable for amide bonds formation. Figure 1 shows the IR spectrum of all the

synthesized materials, together with a table showing the most characteristic

bands. For BC, the broad band at 3341 cm-1 corresponds to stretching vibrations

of the O-H bond that is present in the cellulose structure. The small signal

seen at 2882 cm-1 is characteristic of stretching of the C-H bond (OH, et al.,

2005). Additionally, the band at 1630 cm-1 is due to the bending of the H-O-H

bond of water, given BC-TOCN´s highly hydrophilic nature. The band at 1316 cm-1

corresponds to the (C6) CH2 stretching. Additionally, at 1159 and 1107 cm-1

signs of stretching and symmetric and asymmetric elongations of the C-O-C were

observed. The signals at 1056 and 1031 cm-1 are characteristic of skeletal

vibrations involving C-O stretching of the pyranose ring (KONDO & SAWATARI,

1996; DUBEY, et al., 2017). On the other hand, for the BC-TOCN, the band at 1601

cm-1 corresponding to the COO-stretching is observed, which confirms the

presence of carboxylate moieties in BC-TOCN. Additionally, in this band a

shoulder is observed at 1632 cm-1, which is due to the presence of aldehyde and

carbonyl groups, which end up overlapping (CHITBANYONG, PISUTPICHED,

KHANTAYANUWONG, THEERAGOOL, & PUANGSIN, 2020). Additionally, in BC-TOCN-AMD-C12

and C18, as a product of the amidation of the material, a high increase in the

signals attributed to the stretching of the methyl (–CH3) and methylene (–CH2)

groups is observed at 2954 y 2850 cm-1 of the aliphatic chains of the amines.

And significantly, the signals that confirm the presence of the amine group

correspond to the overlapping broad band of amide I and amide II at 1643 y 1569

cm-1 respectively (LASSEUGUETTE, 2008; GÓMEZ, COMBARIZA, & BLANCO TIRADO, 2017).

Likewise, Figure 1 shows the SEM images of these materials. In the BC (Figure

1.a) the morphology of the bacterias that produce bacterial cellulose, the

gluconacetobacter xylinus, can be observed, even adhered to it since its

production occurs extracellularly (SAAVEDRA SANABRIA, et al., 2021). In

addition, when comparing the change that occurred after oxidation via TEMPO and

mechanical defibrillation (Figure 1.b), the separated BC-TOCN can be observed

forming networks, with diameters at the nanometric scale. Researchers report

similar morphologies and sizes, such as those reported by OVALLE SERRANO, GÓMEZ,

BLANCO TIRADO, & COMBARIZA (2018) who observed diameters around 100 nm, and

those reported by LIU, et al., (2016) with diameters between 200 nm and 1.5 μm.

Additionally, for BC-TOCN-AMD-C12 and C18 (Figure 1.c.d) the cellulose fibers

are observed, some wider than others and adhered to them, which could correspond

to the coupling of the grafted amines in the form of sheets. However, it can be

inferred that its morphology does not change drastically as reported in similar

studies GÓMEZ, COMBARIZA, & BLANCO TIRADO (2017).

On the other hand, regarding thermal degradation processes, for BC the point of

maximum decomposition of its structure occurs at 342 °C with a mass loss of

58.99% and for BC-TOCN it occurs at 303 °C , that is, there is a decrease in

thermal stability (FUKUZUMI, SAITO, OKITA, & ISOGAI, 2010) with a mass loss of

19.71%. This is explained by the presence of carboxylic units that favor the

decomposition of BC, facilitating the transitions from solid phase to gas

through decarboxylation reactions. Also for the BC-TOCN, a shoulder can be seen

at a temperature of 232 °C with a weight loss of 14.44%, which corresponds to

the decomposition of the carboxylic units on the BC-TOCN surface. Additionally,

in BC-TOCN-AMD-C12 and C18 thermal decomposition events were observed near 200

°C, possibly attributed to the volatilization of the hydrocarbon chains of the

primary amines (CALDERÓN VERGARA, OVALLE SERRANO, BLANCO TIRADO, & COMBARIZA,

2019). In addition, the thermal degradation temperature for the amidated

derivatives at 318 °C for AMD C-12 BC-TOCN and 317 °C for AMD C-18 BC-TOCN, is

higher than for BC-TOCN. This indicates that the coupling of the primary amines

leads to an apparent improvement in the thermal resistance of BC-TOCN.

Additionally, the colloidal stability of BC-TOCN was analyzed by means of the Z

potential. Thus, a value of -60.8 mV was obtained, inferring a good colloidal

stability probably in response to the amount of negatively charged carboxyl

groups COO- on the surface of the cellulose structure, which causes

electrostatic repulsions that prevent the suspension from agglomerating

(MAHENDRAN & RANJITHA KUMARI, 2016).

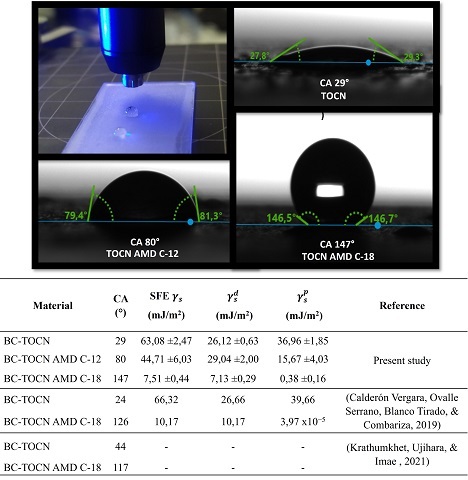

On the other hand, the contact angle (CA) tests were performed with a double

injector using the double sessile drop measurement method, depositing drops of

water and diiodomethane, as shown in figure 2. For the BC-TOCN films, a contact

angle to water of 29°, evidencing its highly hydrophilic nature corresponding to

the presence of polar groups (–OH and –COOH) on the surface. As for the

materials modified with primary amines, an increase from 29° to 80° was observed

with BC-TOCN-AMD-C-12 and 147° with BC-TOCN-AMD-C-18, corresponding to the

presence of the alkyl chains of dodecylamine and octadecylamine nonpolar nature,

which coupled to the BC-TOCN surface. Comparing the results obtained, it is

observed that the increase in hydrophobicity obtained with octadecylamine is

higher than in other studies. However, with dodecylamine this increase was not

as significant, but higher than that reported by GÓMEZ, COMBARIZA, & BLANCO

TIRADO (2017). In addition, with the experimental values of the contact angles

of water and diiodomethane with the films, the surface free energy (SFE) was

obtained γ_s and the polar components γ_s^p and dispersive γ_s^d (Figure 2).

Indeed, it is observed that BC-TOCN obtained values of SFE and its components

very similar to those obtained by the investigation of CALDERÓN VERGARA, OVALLE

SERRANO, BLANCO TIRADO, & COMBARIZA (2019) with BC-TOCN from fique.

Additionally, they are within the ranges reported by authors such as KHOSHKAVA &

KAMAL (2013) in nanocrystalline cellulose with SFE values of 66 mJ/m2

characteristic of materials with a hydrophilic nature. Likewise, as the higher

value of the polar component on the dispersive that indicates hydrogen bond,

inductive and acid-base interactions. Unlike the materials modified with amines,

with which it was possible to demonstrate that amidation decreases the SFE of

the materials, especially the one coupled with octadecylamine whose value was

7,5 mJ/m2, very similar to that reported by CALDERÓN VERGARA, OVALLE SERRANO,

BLANCO TIRADO, & COMBARIZA (2019). Additionally, the polar component decreases

drastically, being lower than the dispersive component, which indicates Van der

Waals type interactions, characteristic of hydrophobic materials.

Conclusões

Contact angle measurement indicated the coupling of the primary amines with the

procedures used. This is supported by the appearance of new signals in the IR

spectrum attributed to the formation of amide bonds. Likewise, a slight increase

in the decomposition temperature of the amidated materials with respect to TOCN

was observed. On the other hand, morphological and dimensional changes of the BC

surface and its modifications were observed, inferring that the oxidation via

TEMPO combined with ultrasound effectively leads to the separation of the

nanofibers. In addition, the apparent coupling of the amines to TOCN is observed.

Likewise, as a result of CA and SFE, the hydrophobization of the material was

corroborated, reaching contact angles with octadecylamine of up to 147° and SFE

values of 7.5 mJ/m2, which are consistent with its chemical structure. Which

indicates that the resulting materials have good potential to be used as additives

in biopackaging given their biocompatibility, degradability, along with

hydrophobicity and improvement in their properties.

Agradecimentos

We thank the Guatiguará Technology Park at Universidad Industrial de Santander for

infrastructural support. To Minciencias and the Universidad Industrial de

Santander for financing the postgraduate project of Maria Andrea Gamboa.

Referências

BALASUBRAMANIAM, S. L., PATEL, A. S., & NAYAK, B. (2020). Surface modification of cellulose nanofiber film with fatty acids for developing renewable hydrophobic food packaging. Food Packaging and Shelf Life, 26. doi:10.1016/j.fpsl.2020.100587

CALDERÓN VERGARA, L. A., OVALLE SERRANO, S. A., BLANCO TIRADO, C., & COMBARIZA, M. Y. (November de 2019). Influence of post-oxidation reactions on the physicochemical properties of TEMPO-oxidized cellulose nanofibers before and after amidation. Cellulose, 27, 1273–1288. doi:10.1007/s10570-019-02849-4

CHITBANYONG, K., PISUTPICHED, S., KHANTAYANUWONG, S., THEERAGOOL, G., & PUANGSIN, B. (November de 2020). TEMPO-oxidized cellulose nanofibril film from nano-structured bacterial cellulose derived from the recently developed thermotolerant Komagataeibacter xylinus C30 and Komagataeibacter oboediens R37–9 strains. International Journal of Biological Macromolecules, 163(15), 1908-1914. doi:10.1016/j.ijbiomac.2020.09.124

COSTELLO, A., ABBAS, M., ALLEN, A., BALL, S., BELLAMY, R., FRIEL, S., . . . JOHNSON ANNE. (2009). Managing the health effects of climate change. Lancet, 373(9676), 1693-1733.

DUBEY, S., SHARMA, R. K., AGARWAL, P., SINGH, J., SINHA, N., & SINGH, R. P. (March de 2017). From rotten grapes to industrial exploitation: Komagataeibacter europaeus SGP37, a micro-factory for macroscale production of bacterial nanocellulose. International Journal of Biological Macromolecules, 96, 52-60. doi:10.1016/j.ijbiomac.2016.12.016

FUKUZUMI, H., SAITO, T., OKITA, Y., & ISOGAI, A. (September de 2010). Thermal stabilization of TEMPO-oxidized cellulose. Polymer Degradation and Stability, 95(9), 1502-1508. doi:10.1016/j.polymdegradstab.2010.06.015

GÓMEZ, F. N., COMBARIZA, M. Y., & BLANCO TIRADO, C. (2017). Facile cellulose nanofibrils amidation using a ‘one-pot’. Cellulose, 24, 717–730. doi:10.1007/s10570-016-1174-9

KONDO, T., & SAWATARI, C. (1996). A Fourier transform infrared spectroscopic analysis of the character of hydrogen bonds in amorphous cellulose. Polymer, 37(3), 393-399.

MAHENDRAN, G., & RANJITHA KUMARI, B. D. (December de 2016). Biological activities of silver nanoparticles from Nothapodytes nimmoniana (Graham) Mabb. fruit extracts. Food Science and Human Wellness, 5(4), 207-218. doi:10.1016/j.fshw.2016.10.001

OH, S. Y., YOO, D. I., SHIN, Y., KIM, H. C., KIM, H. Y., CHUNG, Y. S., . . . YOUK, J. H. (September de 2005). Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydrate Research, 340, 2376–2391. doi:10.1016/j.carres.2005.08.007

OVALLE SERRANO, S. A., GÓMEZ, F. N., BLANCO TIRADO, C., & COMBARIZA, M. Y. (February de 2018). Isolation and characterization of cellulose nanofibrils from Colombian Fique decortication by-products. Carbohydrate Polymers, 189, 169-177. doi:10.1016/j.carbpol.2018.02.031

PENG, S. X., CHANG, H., KUMAR, S., MOON, R. J., & YOUNGBLOOD, J. P. (march de 2016). A comparative guide to controlled hydrophobization of cellulose nanocrystals via surface esterification. Cellulose, 23(3), 1825-1846.

SAAVEDRA SANABRIA, O. L., DURÁN, D., CABEZAS, J., HERNÁNDEZ, I., BLANCO TIRADO, C., & COMBARIZA, M. Y. (November de 2021). Cellulose biosynthesis using simple sugars available in residual cacao mucilage exudate. Carbohydrate Polymers, 274(15). doi:10.1016/j.carbpol.2021.118645

SHEN, M., SONG, B., ZENG, G., ZHANG, Y., HUANG, W., WEN, X., & TANG, W. (August de 2020). Are biodegradable plastics a promising solution to solve the global plastic pollution? Environmental Pollution, 263.

SIRVIO, J. A., VISANKO, M., LAITINEN, O., AMMALA, A., & LIIMATAINEN, H. (2016). Amino-modified cellulose nanocrystals with adjustable hydrophobicity from combined regioselective oxidation and reductive amination. Carbohydrate Polymers, 136, 581-587. doi:10.1016/j.carbpol.2015.09.089

TAUBNER, T., COPÍKOVÁ, J., HAVELKA , P., & SYNYTSYA, A. (May de 2013). Preparation of amidated derivatives of monocarboxy cellulose. cellulose, 20, 2045–2055. doi:10.1007/s10570-013-9938-y

WANG, J., TAVAKOLI, J., & TANG, Y. (September de 2019). Bacterial cellulose production, properties and applications with different culture methods – A review. Carbohydrate Polymers, 219, 63-76. doi:10.1016/j.carbpol.2019.05.008